Products Overview

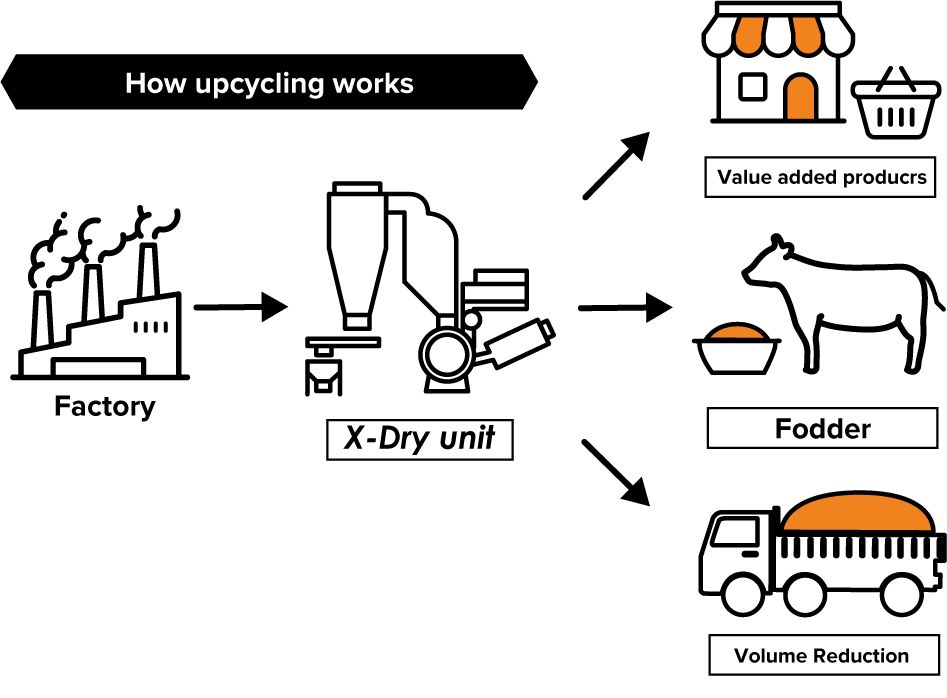

Contribute to the SDGs with Upcycling

Waste from food factories contains a lot of water due to the water contained in the food itself

and the water added during the manufacturing process.

Although there is still some food that can be utilized, most of them are disposed of due to spoilage.

We have developed Food Drying Machin as a way to make effective use of such waste.

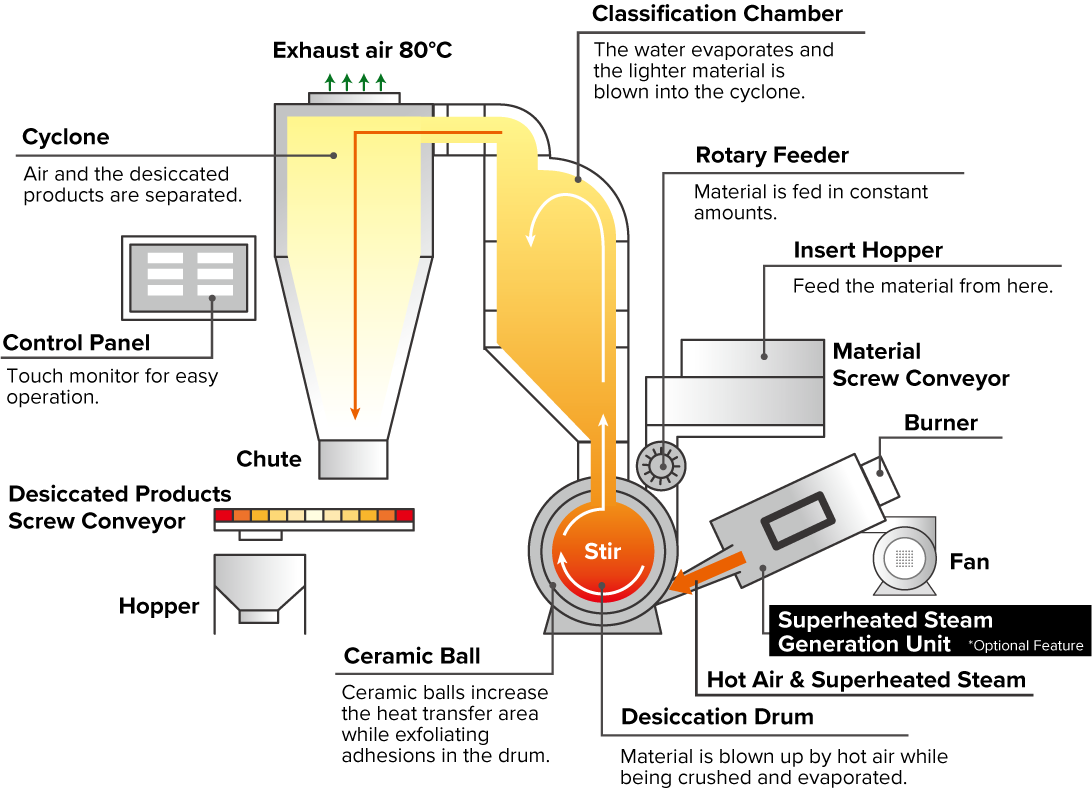

Desiccation Mechanism

The material supplied from the rotary feeder is blown up by the classification chamber

while being stirred by hot air and ceramic balls in the drying drum.

Dried products whose moisture has evaporated are sent from the classification chamber to a cyclone

and collected from the bottom, while the steam is exhausted from the top.

Feature

01. Speedy Desiccation

The drying time is about 5 seconds.

Minimal damage on food.

High heat efficiency and no burning.

02. Minimal unevenness in moisture content

Heat is evenly applied to the material by the large volume of hot air and the stirring power of ceramic balls.

03. Continuous Desiccation

The production efficiency is high because a large amount of drying can be done quickly by a continuous system.

04. Washable

The whole device can be washed due to its simple structure.

Hygiene is also an advantage.

※Automatic washing option is available

05. Hard to Break

The simple structure with few driving parts makes it difficult to break.

06. Compact

The device is very compact and can be installed in limited factory space.

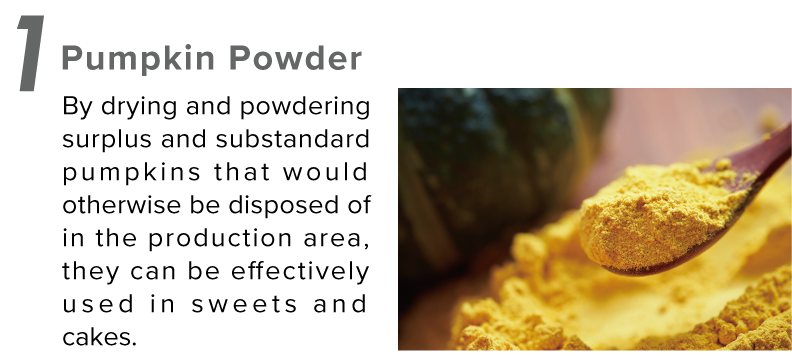

Case of Desiccation

It is possible to upcycle food waste.

Desiccation can be done while retaining the color of each food.

By adjusting the particle size, various usage methods are created.

※We propose equipment in total including supply, discharge,

pretreatment, and pulverization.

Effective use of dried powder